A survey was conducted among industry practitioners and experts on this. Learn more:

When everyone in the industry is focusing on Industry 4.0, Smart Factories, Industrial IOT, AI, Robotics, etc. do concepts of Lean Manufacturing such as 5S, Muda, SMED, etc still hold any relevance?

- Results of the finding

- 10 Used cases for 5S and Industry 4.0 application relevance

#nilakantasrinivasan-j #canopus-business-management-group #B2B-client-centric-growth #5S #Industry-4.0 #MUDA #SMED #Lean-manufacturing

Concept of Wastes as perceived in Lean Standard Work for Manufacturing

Organizations strive to eliminate three basic categories of waste in their business processes.

Basic Waste Category are:

- Wasteful activity – Work that adds no value to a product or service. Eliminating such activities from business processes will help organizations cut cost.

- Unevenness – This denotes inconsistencies that exist in a business process. Unevenness and inconsistencies can be avoided by eliminating inventory and supplying items to the production process only when they are needed.

- Overburden – This is caused by an unreasonable or excessive strain on resources. It can be eliminated by simplifying and standardizing processes.

Among these three basic categories of wastes, Lean focuses on eliminating activities that do not add any value. These activities are further classified into seven types of wastes: transport, inventory, motion, waiting, overproduction, over processing, and defects.

Checksheet for Process Design in Manufacturing Organization

Following are some of the important steps involved in Process Design in Manufacturing Organizations. It can also serve as a check sheet if you are commencing process design in your organization.

- Process flow design for various products

- Decision of in-house manufacturing Vs sourcing

- Plant layout with processes (cell manufacturing as per lean principles)

- Workstation design

- Assembly automation tools selection

- Tooling RFP generation

- SPM RFP generation

- Material handling Design

- Capacity planning – equipment capacity, labor and storage

- Process cycle estimation using industrial engineering

- Project manage the implementation of process design

- Facilitation of machine capability (dependent on tooling design, but we’ll facilitate)

- TAKT time delivery and output optimization

- Labor training on assembly activities

- 5S and material handling standard establishment

- Establishment of quality standards (incoming, in-house and final product)

Following are some of the important steps involved in Process Design in Service Organizations. It can also serve as a check sheet if you are commencing process design in your organization.

- Current state assessment

- Business process definitions

- Agreement on service levels, measures of success and operations metrics

- New process design

- Technology integration

- Process documentation

- Project manage the implementation of process design

- RFP for technology up gradation

- Process pilot

- Process training

- Establish governance mechanisms

- Process reviews/audit mechanism

- What works for large enterprises may not work for mid size organizations! The business transformation professional need to understand what approach suits your organization!

- Business Transformation professional will need vast experience in leading or handling complex change in in different situations across atleast few different sectors and corporate cultures.

- The Business Transformation professional should stay focused on delivering measurable and sustainable results.

- For Business Transformation to be sustainable, the professional leading the change should approach it holistically, rather than as a mere process change. Aspects such as leadership on-boarding, internal mass-communication campaigns, long term transformation roadmap, up-skilling, process re-design, data analysis, automation, process training, on-going process audits and regular reporting should all be integral part of the Business Transformation. If the transformation is of a very large scale, then the entire program office (PMO) should be managed the Business Transformation team.

- The Business Transformation professional should be a hardcore change agent at heart. One who is used to working by rolling up his/her sleeves.

- Now, that’s not just it. He/She has to understand ‘Strategy Execution’, “Digital Business Model’ & ‘Customer Experience’ well enough to make your business transformation efforts futuristic and fruitful.

- Business Transformation professional shouldn’t thrust any specific methodology such as Lean, Six Sigma, Theory of Constraints, Balance Score Card, TRIZ, etc. Instead, use he/her expertise in these areas to do what is relevant your business!

Businesses thrive by growth. Leaders are expected to find innovative ways to propel the organization in the new direction and to make that growth vision a reality. In this game, most of us take for granted, the fact that the processes we own need our attention. I’m not joking. Smart managers are compelled to delegate the monitoring or upkeep of the processes to their smartest subordinates; And conveniently focus their own energy on transforming the business.

Unfortunately Murphy plays havoc, all the time. In reality, time goes in fire fighting, leaving none or very little for change or transformation effort. In fact, the more you plan to devote time for transformation, the more you plough your head into daily issues. The time that you devote to unplanned daily issues can be equated to a cache, such as the one in your computer, except that this one is a ‘Management Cache’.

It stitches together a set of simple tools and techniques to put the concept into action. It takes an integrated approach. In fact, the lack of an integrated approach to daily work management is often recognized as the root cause of fire-fighting, because even a manager who is diligent, soon or later swirls into fire fighting.

Nichijo Kanri integrates role definition as defined by HR, process specification and standards as defined by process experts, individual potential and collaboration efforts. It uses tools such as Managing Points, Checking Points (MPCP), check sheets, visual management methods, gemba walks, huddles, accountability circles, kaizen, etc

Whether you are small business owner or a senior management professional in a mature corporate set-up, Daily Work Management System can revive & restart your system that clears the management cache and gives you peace of mind. It is fuel you to scale up your organization and, in fact, even fuel your own growth prospects.

If you wish to implement Daily Work Management System in your organization, pls feel free to contact us.

As an entrepreneur or subject matter expert, building an product or service isn’t really difficult because you have all the ideas are packed in your head. In fact that is true for any one skilled professional. Unfortunately that doesn’t guarantee success when it comes launching a successful product or service.

Customers will choose or recommend products that best address their needs. Here’s an interesting real life story of a Jewish immigrant couple trying to meet their ends. In this process they end up building a business empire. I read this story in the book ‘Outliers: The Story of Success’ by Malcolm Gladwell.

Louis and Regina Borgenicht landed in America in the year 1889 as immigrants. Louis was struggling to feed his family of four. He tried various odd jobs with little or no success. He was desperate and was about to quit.

Here’s an extract from the book:

“The answer came to him after five long days of walking up and down the streets of the Lower East Side, just as he was about to give up hope. He was sitting on an overturned box, eating a late lunch of the sandwiches Regina had made for him. It was clothes. Everywhere around him stores were opening—suits, dresses, overalls, shirts, skirts, blouses, trousers, all made and ready to be worn.

Borgenicht took out a small notebook. Everywhere he went, he wrote down what people were wearing and what was for sale—mens wear, women’s wear, children’s wear. He wanted to find a “novel” item, something that people would wear that was not being sold in the stores. For four more days he walked the streets. On the evening of the final day as he walked toward home, he saw a half dozen girls playing hopscotch. One of the girls was wearing a tiny embroidered apron over her dress, cut low in the front with a tie in the back, and it struck him, suddenly, that in his previous days of relentlessly inventorying the clothing shops of the Lower East Side, he had never seen one of those aprons for sale.”

Rest of it is rags-to-riches story. The couple built a thriving business and a niche for women and kids apparels.

This lesson of success hasn’t changed with time. If you want to be the Borgenicht of your business line, then let the designing your new product start with what we define as ‘Gemba’. It is a Japanese word implying ‘the real place’. Borgenicht painstakingly yet meticulously gathered insights from Gemba. For your products or service, ‘the real place’ is where it is been used by your consumers. Hence ‘Gemba’ is the fountainhead of your new product ideas and implementation roadmap. Market Research is supposed to do that, but in today’s world, it is outsourced to an agency. Market research reports contain only tangible factors but Gemba insights are missed or misunderstood.

If you have a new product or service development lined up, it would be in your own interest that you visit ‘Gemba’ and gather insights that will feed to the success of your product rather than review the new product development plan in the board room sipping green tea and munching cookies.

Consider a Gemba visit for the following:

- Deciding your target segment

- Who will buy our products and who will not?

- Understanding common needs of different customer groups

- Understanding articulated and unarticulated customer needs

- Understanding customer journeys

- Understanding substitutes and alternates for your product

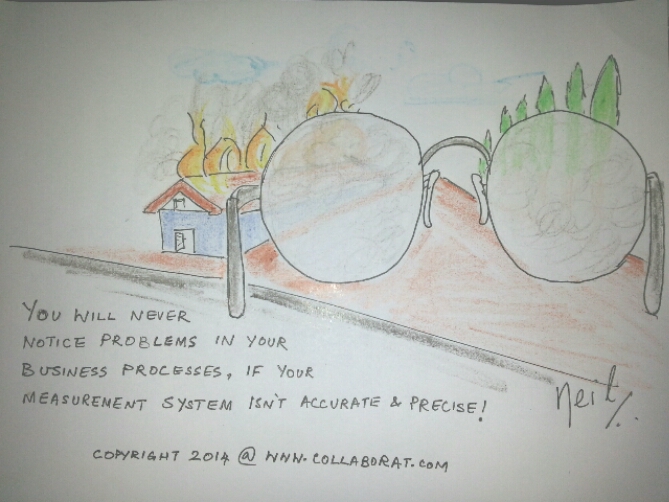

You will never notice problems in your business processes, if your measurement system isn’t accurate & precise.

You will never notice problems in your business processes, if your measurement system isn’t accurate & precise.

Indeed they are different; Most widely accepted definition of a consultant is an expert or a professional in a specific field and has a wide knowledge of the subject matter and one who provides advice in that field.

So by definition a consultant has very limited execution responsibility. However commercialization of the ‘Consulting Industry’ and intense competition has led to a situation where firms promise to own or share responsibility of execution. But in reality, they primarily role is to advise so things fall through the cracks as the engagement proceeds.

Due to their envious position as subject matter experts, consultants usually have an upper hand in their relationship with clients. Many times, this biased relationship is not very conducive for building trust and confidence between both the parties.

“The test of a good consultant is not whether he or she has generated a unique insight, but whether the insight can be applied to produce positive results. Consultants can’t just be smart; they have to be capable of delivering a business outcome” – The Economist

That is why consultants are usually criticized for the following:

- Theorizing problems and making them difficult to comprehend

- Heavy usage of Jargon!

- Force problems into a ‘methodology’ they know

- Attempt to make projects bigger or longer than they need to be

- Produce an elaborate dossier called ‘Project Report’ that reiterates the problem

Not all consultants have such deficiencies, but it is very prevalent.

‘Collaboration’ on the other hand is a recursive process where two or more people or organizations work together intersection of common goals – for example, an intellectual endeavor that is creative in nature -by sharing knowledge, learning and building consensus. Collaboration does not require directive leadership and can sometimes bring better results through decentralization and egalitarianism.

Traditionally, collaboration is widely popular among authors, academicians & researchers. These are fields where two or more experts with diverse and varied experience work together to towards a common goal. So ‘execution & result orientation’ is at the heart of collaboration. And unlike consulting, there is no role to just ‘advise’ and not own execution.

Good collaboration has the following elements:

- Tactical – Where one tells other teams members specifically what to do in his/her areas of expertise

- Tacit – Where one trains other members on how to handle issues/situations beyond technical stuff

- Co-delivery – Where one dirties his/her hands and work together with the team

- Partnership – Where one recognizes that they are not experts in all disciplines. Hence he/she partners with other experts in the team

There is no need to emphasis which one is better when it comes to ‘change management’. Collaborative style of change management is several notches above consultative style.

Known in short as Neil, Nilakantasrinivasan helps individuals and organizations to improve their performance, profitability and processes.

He is an expert in Operations Management, Customer Experience & Project Management.

Neil’s approach is not to prescribe any ‘methodology’. Instead he uses his experience with Hoshin Kanri, Balance Scorecard, LEAN, TQM, Six Sigma, Triz, Theory of Constraints, Knowledge Management, industrial engineering methods, ISO, PCMM, etc to deliver a composite solution that will resolve the pain points and improve profitability, productivity & process.

Sign-up for collaborat newsletter