Lean Six Sigma Project – A beginner’s guide is a series that explains how to run Lean Six Sigma projects in detail. The biggest benefit of combining Lean and Six Sigma is to deliver more value to customers and business. In order for a Six Sigma Green Belt to be successful with a project, they must know what’s to be done, and how to accomplish them! This guide is a step-by-step procedure to execute the 5 phases of a Lean Six Sigma project.

Lean Six Sigma improvement projects follow 5 phase DMAIC approach. A six sigma project is not an academic exercise, but its primary objective is to impact customers, business, and employees positively. Thus stakeholder buy-in and sponsorship are very important factors for its success. Every project should have at least one project sponsor (One sponsor is just fine, two is OK, but greater than that is undesirable). The project sponsor is usually the process owner or a senior management executive who is accountable for the overall project and its success. They take the lead in identifying the project & its objectives, and in team formation. The team composition should be cross-functional. The sponsor also has to decide whether this Six Sigma project should be led by a Black Belt or Green Belt. Once identified, the respective Six Sigma Belt plays the lead role in the project. It is their responsibility to complete the project on time, and deliver desired results. Now, for the remaining part of this beginner’s guide, let’s assume that it is a Lean Six Sigma Green Belt Project. The duration of a typical project should be between 3 to 4 months. The overall project plan for all Six Sigma improvement projects are mapped to Define, Measure, Analyze, Improve, and Control. There are defined deliverables for each of these phases which have to be accomplished before progressing further. At the end of each phase, a formal tollgate is used to stage a gate review by the sponsors. Various Six Sigma concepts and tools can be applied to progress and accomplish desired phase-wise outcomes. In order to make sure the project meets the timeline, and set-out objectives; the Green belt and team members are to meet regularly. In addition to this, Six Sigma Green Belts are mentored by Black Belts or Master Black Belts. In a nutshell, following are the broad outlines for each of the DMAIC phases of Lean Six Sigma Project:

- Define – Identify the project objective and define the problem to be solved

- Measure – Collect necessary data regarding the problem and establish current performance

- Analyze – Use the data collected to analyze and screen factors which are the root causes for a problem

- Improve – Identify suitable solutions to overcome the root causes

- Control – Implement the solutions and monitor its results

Next, as a part of this beginner’s guide, let’s understand how to accomplish the deliverable of the Define phase here

Define Phase is the first phase of Lean Six Sigma Project. Following are the deliverable of this phase:

- Develop the Project Charter

- Identify the Project CTQ

- Create Process Maps

Develop the Project Charter

Project Charter is an important document that summarizes the purpose, current scenario & goal, measures of success (CTQ), project’s scope, quantitative & indicative project benefits, and team members. This is the most important document, as it creates a term of reference for this entire Lean Six Sigma project. In order to prepare the project charter, several meetings and preparatory steps may be needed. In some cases, gathering the Voice of Customer (VOC) may be required to even understand the problem. Project Scoping determines exactly how the project will contribute to overall business, whether the efforts will be diverted to maximum impact area, team composition, financial resources required, etc. In Six Sigma, a tool called ‘In-Frame Out-Frame’ is used to decide on the scope. Six Sigma Green Belt should closely work with the Project Sponsor to complete the Project Charter.

Identify the Project CTQ

CTQ refers to Critical to Quality metric. This is a measure of success for the project. Usually, there is only one CTQ for DMAIC projects. It can either be a measure of efficiency or effectiveness. However, it is a key performance indicator for Voice of Customer or Voice of Business. Further, it should be measurable. Usually, its indicative or accurate current performance is reported in the project charter. The above two deliverable run parallel, and they are of significant importance because they mark the formal kick-off of the project, team member induction, Lean Six Sigma training (if not included earlier).

Create Process Maps

In order to understand the end-to-end process; a detailed process document is created by the team. However, in case such documentation already exists, then it becomes easy for the project team members to revisit it.

Six Sigma Green Belt can involve all her team members in this activity. Two best ways of mapping a process are to interview all the parties involved in the process or to conduct a work-out session with all parties. Latter requires good facilitation skills. Once the process maps have been created, the team can use them to identify the bottlenecks, challenges, issues, inputs & outputs, delays, etc. Essentially, it can be used to decide which part of the process is important, and needs to be introspected. On completion of the above deliverable, a formal define tollgate review is conducted. Then the project moves to Measure Phase.

In a Continuous improvement journey, improvement projects are nothing but the lifeline. In this series of articles, we covered on the Need for Project Selection and the Criteria for project. Now we’ll answer the big question – Where can I get my projects from? Essentially various sources of the project!

Customers Interactions: “Customers” are the biggest source for improvement projects. Classically, negative customer sentiments are good places to start. Your customers are unhappy, so it’s time to fix the issue. Mixed or ambiguous sentiments are also relevant places to start. Customer Complaints:If your organization has a list of customer complaints, then that is an apt place to commence. Complaints are not only sore for your customers, but for you too. Such complaints may cover a vast product or service attributes such as product or service quality, delivery time, responsiveness, people issues, pricing or areas of monetary impact including warranty claims,process & policy issues.· Repeat Complaints: You can go one step further and target repeat complaints instead. Repetitive complaints from the same customer with the same tagging indicates high priority area for improvement.

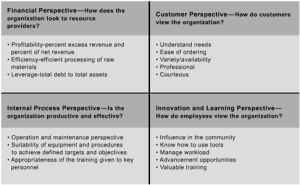

·Enquiries & Requests: Few organizations target the need of customers to call or contact the organization and, reduce them. It might not be a complaint, instead just an enquiry or request. In other words, interactions with the organization that can be avoided. Looking at enquiries and requests serve as a proactive means to identify future problem areas. ·VoC Program output: If your organization conducts structured VoC surveys, then the outputs of such mechanism can be a good source of Continuous Improvement or Lean Six Sigma projects ·Customer Experience (CX) Dipstick: Customer Experience is usually hidden and not so obvious as customer feedback. Structured and unstructured mechanisms can be deployed to understand the customer experience. For example, many organizations now use mystery shopping to unearth issues in customer experience. Observation or Listening posts are also a good way to identify how customer experience can be improved. First Time Right (FTR): If you closely have a look at your company’s process, you will find that there are many internal defects (work-in-progress) occurring, such as rework, repairs & in-process rejections. Such defects are silent killers because they drain organization’s efficiency and effectiveness silently. If your organization is measuring FTR, then its improvement can be an ideal project. More evolved organizations use RTY (Rolled Throughput Yield) as a metric which is also a good place to demonstrate Continuous Improvement. However, most organizations have a simpler measure of success for quality – Defect Rate (% Defective). While there’s nothing wrong with this metric, is a bit holistic and hence factors leading to inefficiencies escape unnoticed with this metric. Nonetheless, it is good starting point for Continuous Improvement projects. Reliability Data/Warranty data: Field failures are sometimes grave. It can cost you a lot and, the overall cost of ownership for customers might increase esp if the warranty is denied or the product is under breakdown. In broader terms, the principle of warranty is to institute accountability in the event of an untimely failure of an item or the inability of the item to perform its intended function. Experts consider reliability data analysis as a quality measure over time. This reliability analysis is done to analyze whether your product will survive for the time defined by the company in the normal conditions. Improving the reliability of a product can work both ways – organizations can lower its operational cost and provide longer warranty and customers would experience break down less often. Process Performance Data: If your organization has a well-defined and structured reporting mechanism for process performance metrics, such as a dashboard or scorecard, then it would be a very good source to identify opportunities for continuous improvement projects. As leadership teams are consumers of such reports, such opportunities can easily gain sponsorship as well. Competitive Benchmarking: Benchmarking is a continuous process of comparing your firm’s or company’s practice to those of the competitors or say most successful competitors. In certain cases, you might not be doing well. For example, having control over the delivery time to the customers. Then this can be taken as a project for improvement in our company. So, to generalize, competitive benchmarking results can also be a good source for Continuous Improvement projects. Business Plans/Strategies: Gap between strategic plan and reality can be the cause of concern for leadership. Sometimes such problems may be because of supporting processes. They can hinder new business plans or strategies. Such process improvement opportunities are also a good source for projects, provided they are scoped well with well-defined objectives & goals. Employee Feedback: While customers don’t see your process but only experience its outcomes, employees have an end to end visibility. They experience problems as customers and can associate inward aspects of such poor experience. Many organizations, pilot their products with employees, because employees are pseudo customers. If you can establish a structured process through which employees are encouraged to share their experience and enable them to take up such opportunities as Continuous Improvement or Lean Six Sigma projects, there’s nothing like it. All the above can serve as a good source for Continuous Improvement or Lean Six Sigma projects.A Balanced Scorecard (BSC) is a strategic performance management framework for measuring the impact of strategic decisions across all organizational drivers of an organization. A BSC provides a wider perspective on strategic decisions made by an organization by measuring the impact on key business drivers such as finance, customer requirements, internal processes, innovation, and growth perspectives.

The BSC was conceived with the intent to overcome the limitations of traditional performance measurement tools. At the basic level, managers utilize it to track the activities of their direct reports and monitor the impact of their actions. At the decision-making level, a BSC is used both as a tool that facilitates strategic decision-making and as one that provides an insight into future performances.

Example of Balanced Scorecard?

An automobile manufacturer embraced BSC as a way to remain competitive in a rapidly evolving sector. The ensuing benchmarks show how BSC permeated into each department to coordinate the delivery of quality products and the ability to offer diverse models.

Sign-up for collaborat newsletter