Floundering teams – A source of failure for six sigma projects… many can’t believe, but it’s true. Aptly ASQ has included this topic in their SSGB BoK. The meaning of Floundering is to struggle or stagger clumsily as if confused. Floundering often results from a lack of clearly established goals, unclear tasks, discomfort with other team members, or due to overwhelming emotions.

Six Sigma projects often fail due to floundered teams. Project sponsors and Six Sigma Green Belts have to address such issues quickly, but they themselves are victims. This amplifies the problem and makes it one of the biggest failure modes for Six Sigma projects. If you aren’t convinced, consider the following:

- Usually six sigma projects are identified by senior leaders and Six Sigma Green Belt & team members are assigned. The strategic intent of the project may not be communicated to the team. They may just be aware of the project goal. This is the first and foremost source of floundering. Sponsor, champion, Six Sigma Green Belt and teams may be on the same page, when it comes to the goal, but beyond that there would be complete disconnect.

- Incorrectly scoped projects, often lead to incomplete or incompetent team composition and unreasonable goals. Both these factors lead to poor decision making, delays & fear of producing poor results.

- After all, when there is discomfort or no consensus among team members, it shows in their decisions, or their progression between tasks.

- Unlike IT projects, Six Sigma projects aren’t full time project engagements. Contribution is voluntary. As a result, the Six Sigma Green Belt exercises very little control over the team members and their participation level. This gives opportunities for negative team dynamics such as:

- Misunderstanding between team members

- Some team members bullying others

- Blabbermouths taking center stage and hi-jacking the main agenda

- Digressing and loosing focus

- Some teams are well organized and show no sign of floundering till it comes to improve phase. Execution might force some team members to dissuade, often leading to conflict and floundering

- The duration of the project and its scope itself can be major reasons for floundering. In today’s world of high attrition and frequent job rotations, longer the project duration, higher the risk of having new team members with different line of thought. There are also projects where the leader herself has changed.

- Sometimes, there could be floundering towards the end of a project too. Usually associated with the confirmation of results and computation of financial benefits on the process CTQ. Teams flounder when they are challenged by the financial approver on the real financial benefit.

Solutions

- Well defined roles of each team member gives more clarity, upfront

- Take up reasonable goals that enhances the confidence of team members rather than overwhelming them

- Reaffirmation of the project objectives time and again

- Regular (weekly) meeting of all team members to review the progress and assignment of work

- Division of labor among team members rather than riding on team leaders efforts

- Monthly presentation to sponsor on progress and course correction

- If the Six Sigma Green Belt notices that some team members are stretched, she needs to act immediately. Speak to the concerned person, his supervisor or the project sponsor

We hope this resource Floundering teams – A source of failure for Six Sigma Projects will help manage your Six Sigma Green Belt projects effectively.

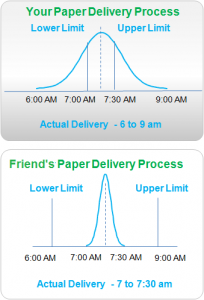

First time, I ever heard the term Six Sigma, I was puzzled, lost and obviously amazed. Here was a term that I couldn’t make out a bit. I felt exactly the same when I first heard H2O from my primary school science teacher. By the way, what is Sigma in Six Sigma? That’s the next question that I wanted someone to answer. The Six Sigma Black Belt who introduced this term to me in a training, gave a very complicated answer, which confused me further. In those days, Google didn’t exist, so I flipped many pages of our company’s Six Sigma manual, and then couple of statistics books, but I finally reconciled. Sigma is the Greek alphabet (in small letters), which is used to represent ‘Standard Deviation’. Sigma (standard deviation) has been in existence since the days of Gauss, who found out the bell shaped curve. But it has become very popular after Motorola coined the term Six Sigma. Now, this methodology has evolved into Lean Six Sigma. Without complicating things for you, Standard Deviation is a measure of variation that exists in any process. The term variation itself is very simple to understand. For example, if your morning newspapers arrive between a time window of 6 to 9 am, while your friend’s newspapers arrive between 7 to 7:30 am, then your ‘newspaper delivery process’ has high variation compared to your friend’s. So, let’s learn standard deviation in layman’s language, so that we can understand what is sigma in Six Sigma in practical sense. Standard Deviation is the average distance of all the data points from their average. Let’s consider the time when your newspaper gets delivered, for a week : Mon – 6:30 am, Tue – 7am, Wed – 6:45 am, Thur – 8 am, Fri – 6 am, Sat – 8:30 am, Sun – 9 am. For this data, the average time when newspaper gets delivered is 7:23 am. So some days delivery is before this time and some days after. Next, you compute the difference between each day’s delivery time and average time for all 7 days, i.e, for Monday : (6:30 am – 7:23 am ) = – 0:53 minutes, and likewise for all values.

Now, we need to calculate the average of all these differences. But the differences you compute will have both minus and plus values. If we add them as such, they will nullify. That wouldn’t work. So, we use the following approach.

- Square all the differences. By doing so, all minus signs will become plus, because (minus x minus = plus) and (plus x plus = plus).

- Now add all the squared differences.

- Divide them by total number of days of data you collected. In this case, it is 7.

- Whatever value you get is already squared, so we have to find its square root.

Finally, the value you get after finding the square root, is the Standard Deviation. For this example, standard deviation or Sigma turns out to be nearly 1 hour (precisely 62 mins). This means that your newspaper boy is on an average one hour ahead or behind than his usual delivery time of 7:23 am. Coming back to our original question, what is Sigma in Six Sigma? So Sigma is a measure of variation in any process. Higher the sigma, higher is the variation, which is undesirable. So, one could compare two similar processes for their Sigma values and find out which one is better. In this case, your friend’s newspaper delivery boy is better than your delivery boy! This will give you a simple idea of What is Sigma in Six Sigma, but this is only understanding half the story. You still need to understand What is Six in Six Sigma in our next article. Six Sigma Certification Course Team

This is the second article in the series that will help understand ‘What is Six in Six Sigma?‘ If you haven’t already read our article ‘What is Sigma in Six Sigma‘, we would like to recommend that you first do so. For now, let’s look into what is Six in Six Sigma. Let’s get started by understanding Customer Requirement and Actual Performance. We are going to use the example of newspaper delivery everyday to your house. As a customer, you want newspapers to be delivered between 7:00 and 7:30 am (say within a half hour window). However, in reality, the paper gets delivered only between 6:00 to 9:00 am (a 3 hour window). So, in this case, the customer requirement or allowable variation is ’30 mins’ while the Actual Performance or Actual Variation is 3 hours. On the contrary, your friend isn’t so particular about his newspaper delivery. He is in fact fine if they are delivered between 6:00 to 9:00 am (a 3 hour window). But in reality, his papers get delivered between 7:00 to 7:30 am (a half hour window). How would you characterize these two situations?

- In your case, actual variation is much higher than allowable customer requirement. In other words, Standard Deviation or Sigma is high.

- In your friend’s case, actual variation is much lower than allowable customer requirement (and so, Standard Deviation or Sigma is low)

Now, let’s answer the question ‘What is Six in Six Sigma?’ Six refers to the Sigma Capability of any process. In this case, the newspaper delivery process. When it’s Six, it means that the Standard Deviation or Sigma is so small that 6 Standard Deviations or 6 Sigmas can be fitted on either side of the bell-shaped curve. Based on the principle of bell-shaped curve (normal curve), 6 Sigma equals only 3.4 defects per million opportunities. For the newspaper example, it means that if there are 1 million days of newspaper delivery, only on 3.4 days (i.e. 3 or 4 days) of the delivery will be beyond your requirement. So, it is very obvious that your newspaper delivery isn’t at the Six Sigma level, but your friend’s delivery could be. It depends on the value of Standard Deviation. We covered the computation of standard deviation in ‘What is Sigma in Six Sigma’.

Let’s say for your friend’s process, only 5 standard deviations or sigmas can be fitted on either side of the bell-shaped curve, then, his sigma capability is at 5 or his newspaper delivery process is at 5 Sigma. To sum up, if you want a particular process to be at Six Sigma, then you will have to manage the following: Understand what the customer requirement is? If there is a window within which the customer wants her delivery or quality, then that becomes your customer requirement.

- Use the data of process performance to compute the standard deviation.

- Assess if the Standard Deviation or Sigma of the process is small enough, that 6 Sigmas can be fitted on either side of the customer requirement window.

- Let’s say your process isn’t at Six Sigma then to find out the sigma value you can either use Sigma Capability Table, Normal Distribution Table or Sigma Calculator. Details of how to compute Sigma for any process is covered in detail in our Six Sigma Green Belt Course.

Six Sigma has evolved as a management discipline for improving processes, and providing customer delight. Some organizations like GE had adopted Six Sigma as their management philosophy. So, Why Six Sigma? Why not follow other approaches like TQM, SCM, COPC, ISO, etc. Let’s understand why many organizations choose Six Sigma over other approaches; and how they benefited. There are 3 key salient features of Six Sigma that are noteworthy:

- Customer Centricity

- Process Orientation

- Fact Based Decision Making

Customer Centricity

While the emphasis on building business processes to meet customer requirements was first proposed by Joseph Juran & Edward Deming (fathers of modern Quality movement); it was taken seriously only with the advent of Six Sigma. Gathering the Voice of Customer and translating these requirements into product features, aka Quality Function Deployment (QFD), were loosely used in TQM. Whereas, in Six Sigma Voice of Customers (VOC) is the starting point. Operational measures and performance measures (KPIs) are built based on VOC. These measures are called as CTQ (Critical To Quality). Customers’ needs constantly change. Such changing needs mean that processes also need to adapt and evolve. Six Sigma enables achieving this adaptation. While creating a new product or service line; the entire system is built to meet customer requirements. Such an approach is called as Design for Six Sigma (DFSS).

Process Orientation

Six Sigma builds strong process orientation within the organization. In Six Sigma, virtually every department, activity, or task is perceived as a process in itself or process step. What does that mean? It means a lot! Every process produces few outputs, and in turn; requires few inputs. Outputs are consumed by Customers (internal or external); and inputs are provided by Suppliers. Such visualization is called as SIPOC in Six Sigma. This helps organizations to move away from the mind-set of fixing people when things don’t work; to fixing processes. In order to improve the outputs of any process or department, its process steps and inputs needs to be improved, and sometimes suppliers need to be educated. People are never penalized in Six Sigma! Traditionally many industries & functions are regarded as ‘people’ driven. For instance, industries such as Hospitality, Entertainment & most service lines and functions such as HR, Marketing, Sales, Admin. Six Sigma organizations treat these as just another process. As a result, the dependency on individuals is also reduced. Organizational silos are challenged and processes are simplified. Driving strong process orientation across the organization has resulted in unbelievable tangible and intangible benefits to customers and organizations. GE is a pioneer in driving process orientation in its Financial Service businesses.

Fact Based Decision Making

Once organizations establish process orientation; access to data and factual information will increase. This presents the next big opportunity for organizations. Across levels, organizations are dependent on their managers to take right decisions. Most often, these decisions are punctuated by decision maker’s bias and personal intuition. Wrong decisions are costly and usually borne by the organization. Six Sigma’s bouquet of tools enables data or fact based decision making. This means the overall management is much more efficient and accurate. DMAIC, an acronym for Define, Measure, Analyze, Improve and Control, is a method used for solving problems. There are over 50 qualitative and quantitative tools which are part of DMAIC. These tools can be applied in several stand-alone situations too. These tools enable data or fact based decision making. At a personal level, an individual practicing Six Sigma over a period time is more efficient and effective than her peers. This has direct impact on career and growth prospects. Thus Six Sigma is a powerful approach which is not only beneficial to organizations; but also to individuals. If you are interested in Six Sigma Certification Courses, visit our products page. Click here

A matrix diagram, also called a matrix chart, is a management and planning tool used for identifying relationships between two to four groups of elements or among elements in a single group. The elements in different groups are placed in rows and columns and relationships among them are analyzed by the team.

Symbols indicating the strength of the relationships are then entered in the cell where the row and column of the two elements intersect. If there is no relationship, then it is left blank. Because matrix diagrams help you analyze data, they are also extensively used in the Measure and Analyze phases of the DMAIC methodology.

- Relationships among different sets of items by comparing them, especially many-to-many relationships among them instead of one-to-one relationships.

- The strength of the relationship between different sets of items qualitatively.

- And, the success of a process that generates one set of items from another set of items.

Sign-up for collaborat newsletter