As a Management Consultant, clients expect you to diagnose, analysis and synthesize to solve their problems or help them create new opportunities.

Tools of Lean Six Sigma help to challenge and change the status-quo.

So there should be no doubt about its relevance to your career. It will certainly help you in long run.

Management Consulting Firms expect candidates to be familiar with several management approaches and Lean Six Sigma is one of them. There are many more such as ToC, System Thinking, Design Thinking, etc.,

Well, if your question is about getting through in the interview of a management consulting firm, then I should confess that having a professional certification will not be the only reason to hire you. Think about it this way, if there is a better candidate without a professional certification, how much does it take for a top notch management consulting firm to provide them the training and get them certified?

That’s exactly what a top notch management consulting firm has done. It has got over 100 of its associates including Consultants, Senior Consultants, Managers and Directors Lean Six Sigma Green Belt Certified by

www.sixsigmacertificationcourse.com

Analyze Phase of Lean Six Sigma Project is the third phase. Following are the deliverable of this phase that Six Sigma Green Belt should deliver with her team:

- Statistically validate root causes

- Perform Value Stream Mapping & Process Value Analysis

- Control & Impact Matrix

Statistically Validate Root Causes

The data that has been collected in the Measure Phase is used to draw statistical associations between CTQ measures and causes. The causes that are statistically significant are the root causes. There are a variety of statistical tools to establish this association. Depending on the type of data – continuous or discrete – tools are selected. Such tests are generally called as Hypothesis tests. 2-t Test, Z-test, t-test, ANOVA, Chi-Square Test, Correlation, Regression, etc., are few common hypothesis tests. The procedure to perform, and interpret all the above tests are usually covered in detail in Lean Six Sigma Green Belt Training programs.Perform Value Stream Mapping & Process Value Analysis

Control-Impact Matrix

The final deliverable of the Analyze phase is to summarize all the findings from Statistical validation or Process Value Analysis (& VSM) in a 2×2 matrix called as Control-Impact Matrix. It is important to ensure that the project doesn’t end up as an academic exercise or research study. Hence, the Lean Six Sigma team needs to identify root causes which have high impact, and well within the control of the team. This is done through a team discussion with the involvement of the project sponsor. Once the root causes have been identified, & a formal Analyze Tollgate review is completed; the Lean Six Sigma Project is ready to move to the Improve Phase.In a recent Lean Six Sigma Project kick-off meeting of one of my clients, after the teams presented their project charters, the business leader made an extempore announcement that the best and most successful Lean Six Sigma project will receive a special recognition and the team members will be lucratively rewarded.

Immediately few of them wanted to know what criteria will be used for selection. The business leader indicated that I will be the one who will define the criteria for successful Lean Six Sigma Project.

Factors that I consider among the criteria for success of Lean Six Sigma Projects are arranged in the descending order of their importance in the below list:

- Project Scope – Lean Six Sigma projects without well defined scope are bound to fail, but they end up creating a lot of mess around. Scope usually refers to the boundaries of any project. A poorly defined project is one which hasn’t balanced the Project Goal, Scope and Timelines. Also, poorly communicated scope and not defining what is out of scope are equally important and to be addressed.

- Retains interest and commitment of the resources – Improvement projects are successful when its team members contribute their best. Lean Six Sigma projects usually challenge the existing paradigm. Hence without whole hearted and continued participation of the team members, no project will be successful. The sponsor/champion and the Green Belt/Black Belt are entrusted to retain the interest and commitment of the resources.

- Attracts adequate buy-in from key stakeholders – Stakeholders of any project could either be the decision makers, important players who influence the decisions or even impacted parties. Successful Lean Six Sigma projects will have to manage the expectations of all the above stakeholders from time to time and create adequate buy-in. Rather than focusing too much on technical root cause analysis, the emphasis should be on how Lean Six Sigma project can bring about mid-to-large scale change in the organization.

- Flawless execution– Immaterial of the breadth and depth of the analysis done in any Lean Six Sigma project, what sticks out is execution. Well led and implemented project is bound to be successful, as even the quality of data collected and analysis is a function of the flawless execution. Adherence to weekly team meetings, project milestones and tollgates reviews are some simple and easy signs to evaluate execution. Further unbiased data collection and analysis, open minded assessment of solutions, in depth piloting and sustained monitoring are additional measures of flawless execution.

- Identifiable impact on customers – As the proof of the pudding is in the eating, so is the success of any Lean Six Sigma in positive impact it creates on customers. Usually organizations evaluate the success of projects based on the performance of the CTQ (before-after studies). While this is definitely a good way to assess the impact, more often than not, such movements in CTQs aren’t felt by the customers. Considering several other business parameters to validate the impact of the CTQ, including post improvement Voice of Customer may be a very good method. For example, a reduction in defects certainly will reduce the rework effort, increase productivity, reduce complaints, apart from increasing customer satisfaction.

- Making a discovery – Any successful Lean Six Sigma project should un-earth something new, make a discovery about the problem. A project without a discovery could mean we are fixing obvious things. In order to ensure the project team makes a discovery, the quality of work done in the Measure and Analyze phase have to be evaluated. Have the teams identified all possible causes to the problem? Have they collected data of good quality and quantity? Have they holistically analyzed the data to make the discovery? And finally what is the discovery?

Based on my experience with Lean Six Sigma in the last 2 decades, I would consider these 6 factors as significant elements of successful project.

While leaders strive to build a culture of continuous improvement (CI) in their organizations, it is equally important to understand that business-as-usual activities take precedence over improvement activities. CI programs commence with a big bang and a lot of enthusiasm, but time wears out even the strongest and what it leaves behind is mere CI hubbub. This is not a simple problem to solve. If you have been part of any enterprise-wide CI deployment, you will have no difficulty relating to this. This problem is complex and has several failure modes.

In this article, I’ll like to highlight a common but significant failure mode – Selection of projects. It’s needless to emphasize that projects play a big role in any CI journey, but to its disgrace, projects are also a significant contributor to the downfall of CI program.

Going overboard and having too many concurrent projects is one way to fail. Not selecting the right projects to pursue is another. Here are few compelling reasons to consider project selection as an important activity rather than opening the floodgates of projects:

Business Priority: Every business has its own priorities and so it’s important to select the right projects that are aligned with your priorities. Having many dispersed projects will blemish, if not nullify the impact of projects. Alignment between leader’s priority & CI program can be easily accomplished if you select projects right at the beginning.

Change due to competition: If your competition is disrupting the industry, well you better select where you need to improve. External environment often forces organizations ruthlessly reform their way of thinking and working. And today, we all live in a world that is fast changing. So unless your right projects are selected and pursued, your CI program will become redundant soon.

High Customer Expectations: Everyone I talk to says, customers are demanding more than ever before. Understanding the changing their needs and aligning the CI program to customers is vital to the success of any organization’s CI program. Organizations sometimes pursue trivial opportunities such as cost saves but miss on acting on big ticket customer facing projects or customer pain points. Of course, while dealing with customers, things are going to be volatile, but that’s not a reason to avoid them. The good project selection process should filter such project opportunities.

Limited Budgets: All organizations must work within the framework of budgets. Improvements need monetary resources to support the change. Sometimes they are direct and hence easily associated to direct cost centers. But projects with intangible benefits or the ones incurring indirect costs usually end up as scapegoats. If an organization commits to project selection, many such failures can be prevented.

Availability of Resources: Human capital is scarce. CI projects need quality time and mindshare from people of importance in the organization. Quite often resource requirements are never considered during the commencement of projects. Even if considered, it’s only the project leader’s time. As CI projects are a cross-functional effort, active participation of experts from all involved functions defines the success of the project. In order to ensure we get the best out of our teams, we need to time our success. Thus project selection is a time sensitive activity.

Optimizing Number of Projects: Not all the areas of your organization need improvement at the same time, And improvement culture building is a slow and steady process which can never be implemented overnight, nor will the results reap overnight. So getting to rush out the organizational adrenaline may not be a success recipe for good CI program. Selection of projects will ensure that you sustain optimum enthusiasm in the system for CI. So it is very evident that selection of projects impacts the CI culture, employee satisfaction, alignment to customers and ROI to business for the investments it makes in CI in a positive way. In the future articles, we’ll take this one step further and talk about the criteria used for selecting projects.

In a recent Lean Six Sigma Project kick-off meeting of one of my clients, after the teams presented their project charters, the business leader made an extempore announcement that the best and most successful Lean Six Sigma project will receive a special recognition and the team members will be lucratively rewarded. Immediately few of them wanted to know what criteria will be used for selection. The business leader indicated that I will be one who will define the criteria for successful Lean Six Sigma Project.

Factors that I consider among the criteria for success of Lean Six Sigma Projects are arranged in the descending order of their importance in the below list: Project Scope – Lean Six Sigma projects without well-defined scope are bound to fail, but they end up creating a lot of mess around. Scope usually refers to the boundaries of any project. A poorly defined project is one which hasn’t balanced the Project Goal, Scope and Timelines. Also, poorly communicated scope and not defining what is out of scope are equally important.

Retains interest and commitment of the resources – Improvement projects are successful when its team members contribute their best. Lean Six Sigma projects usually challenge the existing paradigm. Hence without the wholehearted and continued participation of the team members, no project will be successful. The sponsor/champion and the Green Belt/Black Belt are entrusted to retain the interest and commitment of the resources. Attracts adequate buy-in from key stakeholders – Stakeholders of any project could either be the decision makers, important players who influence the decisions or even impacted parties. Successful Lean Six Sigma projects will have to manage the expectations of all the above stakeholders from time to time and create adequate buy-in. Rather than focusing too much on technical root cause analysis, the emphasis should be on how Lean Six Sigma project can bring about mid-to-large change in the organization. Flawless execution– Immaterial of the breadth and depth of the analysis done in any Lean Six Sigma project, what sticks out is execution. Well led and implemented the project is bound to be successful, as even the quality of data collected and analysis is a function of the flawless execution. Adherence to weekly team meetings, project milestones, and tollgates reviews are some simple and easy signs to evaluate execution. Further unbiased data collection and analysis, open minded assessment of solutions, in-depth piloting and sustained monitoring are additional measures of flawless execution. Identifiable impact on customers– As the proof of the pudding is in the eating, so is the success of any Lean Six Sigma in positive impact it creates on customers. Usually, organizations evaluate the success of projects based on the performance of the CTQ (before-after studies). While this is definitely a good way to assess the impact, more often than not such movements in CTQs aren’t felt by customers. Considering several other business parameters to validate the impact of the CTQ, including post improvement Voice of Customer may be a very good method. For example, a reduction in defects certainly will reduce the rework effort, increase productivity, reduce complaints, apart from increasing customer satisfaction. Making a discovery – Any successful Lean Six Sigma project should unearth something new, make a discovery about the problem. A project without a discovery could mean we are fixing obvious things. In order to ensure the project team makes a discovery, the quality of work done in the Measure and Analyze phase have to be evaluated. Have the teams identified all possible causes to the problem? Have they collected data of good quality and quantity? Have they holistically analyzed the data to make the discovery? And finally what is the discovery? Based on my experience with Lean Six Sigma in the last 2 decades, I would consider these 6 factors as significant elements of the successful project.Whatever is the nature of your business, innovation is critical today. In order to survive competition and be the customers’ choice, you need to come up with really new products and services. All it means is that your ability to manage the change is a direct measure of your success. In other words, timely launch of new products/services in desired quality and price are going to determine your success, apart from cultural change aspect. So whether you want it or not, good project management skills are essential in today’s business to survive and win. Without digressing on other pre-requisites of good project management, let’s focus on one of most important but rarely focused area.

There are several project management techniques and tools available such CPM, PERT and Critical Chain. Immaterial of the base on which these models are structured, out of my experience, everything finally boils to predicting time duration for a task and the delivering as predicted. In small organizations(less than 10 employees), it is more of coordination, multi-tasking and communication that will determine if a task can be completed as predicted. But with organizations involving a few tens of employees, it is all about how resources and efforts are synchronized. There may be lack of knowledge of what is to be done next, on who owns which piece, how & when to escalate lack of clarity on authority and decision making. Additionally unlike bigger organizations, smaller companies will have to manage with inexperienced and understaffed scenarios. So to make life easy for everyone, if processes associated with project management such as supply chain management processes, finance processes, clearly defined inter-department service levels and authorities, etc., are established well, that will help the organization deliver projects in time. Isn’t this what ‘Process Management’ is all about! Mathematically also it makes sense to focus on process management. For instance, consider the PERT model in which the PERT Time (Task duration) is a function of Optimistic Time (OT), Most Likely Time (MLT) and Pessimistic Time (PT). When OT and PT are wide apart, it means that it is not possible to predict the task duration accurately. In other words, the process on which the task is dependent has high variation. Such a process leads to higher PERT Time. When all the tasks of the project have widely spread OTs and PTs, the overall project duration itself will be high and unpredictable. In order to have closely defined OTs and PTs, we should have confidence that our processes will consistently deliver on-time. In other words, our process should be statistically under control and stable. Again, it’s Process Management!

The Six Sigma is an approach to business process improvement and performance management which encompasses a statistical and method-driven process. In order to effectively deploy the process in your organization, it is necessary to identify the basic elements that drive the Six Sigma methodology. Knowledge of the Six Sigma fundamentals is the first step toward a successful Six Sigma implementation. Before applying any business strategy in an organization, you must identify the goals and benefits of the strategy. You must also recognize the need for such a business strategy in the organization.

Surviving in a business world that is full of competition is crucial to any organization. Six Sigma provides the means to handle declining product prices in the market, which helps any organization compete with the best companies in business. It targets zero defects by setting a common performance goal for the entire organization. Six Sigma helps an organization achieve increased profitability and quality improvement rates, ahead of any of its competitors. Reduced scrap-related costs, rework, improved yield, and increased customer satisfaction are identified in companies striving to achieve Six Sigma.

A Six Sigma initiative differs from other quality improvement methodologies because it ensures that the costs involved in implementation are offset by the gains received from improvements.

The primary goal of Six Sigma is to implement a measurement-based strategy in an organization that concentrates on process improvement and reducing variation. In addition to this, the other important goals of Six Sigma include:

- Reducing the number of defects, leading to the improved quality of a product or service.

- Achieving customer satisfaction by ensuring that customer expectations are met.

- Reducing cycle time, which enables the faster delivery of products.

- And, higher profitability by improving efficiency and effectiveness of the organization.

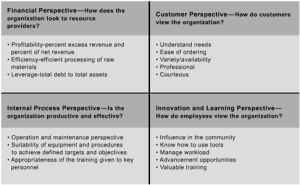

A Balanced Scorecard (BSC) is a strategic performance management framework for measuring the impact of strategic decisions across all organizational drivers of an organization. A BSC provides a wider perspective on strategic decisions made by an organization by measuring the impact on key business drivers such as finance, customer requirements, internal processes, innovation, and growth perspectives.

The BSC was conceived with the intent to overcome the limitations of traditional performance measurement tools. At the basic level, managers utilize it to track the activities of their direct reports and monitor the impact of their actions. At the decision-making level, a BSC is used both as a tool that facilitates strategic decision-making and as one that provides an insight into future performances.

Example of Balanced Scorecard?

An automobile manufacturer embraced BSC as a way to remain competitive in a rapidly evolving sector. The ensuing benchmarks show how BSC permeated into each department to coordinate the delivery of quality products and the ability to offer diverse models.

Total Quality Management (TQM) is a structured system focused on satisfying customers by involving all members of an organization in improving the quality of products, processes, and resources. Sustained customer satisfaction, its main objective, is accomplished through systematic methods for problem solving, breakthrough achievement, and standardization derived from teaching quality leaders such as Philip B. Crosby, W. Edwards Deming, Armand V. Feigenbaum, Kaoru Ishikawa, and Joseph M. Juran. There are no hard-line procedures for implementing TQM. The PDCA cycle, also known as the Shewhart Cycle or the Deming Cycle, is a popular TQM problem-solving tool.

PDCA (The Plan-Do-Check-Act) cycle involves four basic steps for carrying out continuous improvement in a process. Four basic steps of PDCA:

- Plan recognize the opportunity for process improvement and identify the plan for improvement.

- Do the plan is implemented. Simultaneously, employees are trained, and activities such as scheduling and follow-up happen. If the desired process improvement is not achieved, the plan is abandoned and the improvement effort will start from the planning stage.

- Check the implementation of the action plan will yield results. These results are then compared with the planned results. Deviations are recorded and an improvement plan is proposed to achieve results.

- Act on the results of the check step, and a decision is made whether to restart PDCA or standardize on the results.

A value-added activity is any activity that increases the worth of a product or service. It directly contributes to meeting customer requirements, and customers are willing to pay for it. Value-added activities also generate a positive ROI for an organization. Without these activities, the process will be affected. A lean team should analyze if activities in a process actually add value to a product or service. They should also determine if activities in a process can be performed in parallel or be merged. This will help organizations deliver outputs more efficiently.

Example: In a manufacturing process, value-added activities can include: receiving a part request, preparing an internal request for a part from production, finding a relevant plant for issuing a request, finding production availability, updating part request information, and the manager processing the part request information and updating the request.

Non-value-added activities are activities that consume resources and time without adding any value to a service or product. Non-value-added activities do not contribute to customer satisfaction and, therefore, customers are not willing to pay for these activities. They are not important to the production and delivery of a product or service, and eliminating them will not affect a process. Because non-value-added activities do not generate any positive ROI but incur only expenditures, organizations should focus on eliminating them.

Example: In the manufacturing process, non-value-added activities can include: sorting and organizing requests, searching for relevant part production locations, checking locations for availability and delivery, generating production requests, and reviewing the status of requests.

In the Define phase, the Six Sigma team in a software product development company found that customers identified many issues in the beta version of its software.

However, if all the issues raised were to be fixed, timelines would slip and the budget would increase. The team then calculated the number of changes and the time and budget required for fixing these issues in the Measure phase.

In the Analyze phase, the team determined if the changes were aligned with the scope of the project and then identified changes that should be made. It also identified conflicting changes pointed out by the reviewers, communication gaps between the developers and the customers, and ways in which changes were communicated to the developers as other major causes of the issues.

In the Improve phase, the Six Sigma team took several steps, such as determining the limitations of the software, having regular meetings with customers, identifying the appropriate application to communicate the changes to the developers, creating change requests, and monitoring the implementation of the approved changes until closure to eliminate the issues.

Finally, appropriate mechanisms were set up in the Control phase to monitor the regularity of meetings and communication between the developers and customers as well as to monitor the performance and usage of the change request feature.

Sign-up for collaborat newsletter