There are several common ways to improve the existing account growth in B2B companies, including:

- Building strong relationships: Building strong relationships with existing customers is essential for growing their accounts. This can involve regularly communicating with customers, understanding their needs and goals, and going above and beyond to meet their expectations.

- Offering additional products and services: Another way to improve account growth is by offering additional products and services to existing customers. This can help to increase the value of each account, and can also help to cross-sell and up-sell additional products and services.

- Providing excellent customer service: Providing excellent customer service is also key to improving account growth. This can include responding promptly to customer inquiries, addressing customer concerns, and resolving problems in a timely and efficient manner.

- Offering customized solutions: Offering customized solutions to existing customers can help to increase the value of each account. This can include tailoring products and services to meet the specific needs of each customer, and developing specialized solutions that are not available to other customers.

- Implementing customer retention programs: Implementing customer retention programs can help to improve account growth. This can include loyalty programs, referral programs, and other incentives that encourage customers to continue doing business with a company.

- Regularly gathering customer feedback: Regularly gathering customer feedback is another way to improve account growth. This can include conducting surveys, focus groups, and other research to understand customer needs and preferences. This feedback can be used to improve the company’s products or services, and to develop strategies for retaining and growing existing customers.

They are all prescriptive. The question is, which one of these is relevant to your organization and why? That clearly depends on your current state, ground level challenges and growth aspirations. Only by implementing relevant strategies, B2B companies can work to improve the growth of existing accounts and drive sustainable growth for the company.

If you are looking for ways to improve your account growth, click here

#nilakantasrinivasan-j #canopus-business-management-group #B2B-client-centric-growth #Account-growth

3L 5Why Analysis

3L 5Why Analysis is synonymous with Root Cause Analysis nowadays with most organizations having knowledge and know-how to perform 5 Why analysis. Most leaders encourage their leaders to use 5 why analysis to identify the root cause. That’s the good news!

Now the bad news 🙁 Most of the 5 Why analysis are incomplete and provide only tactical means to the current situation. They hardly look at underlying system level causes. If you don’t agree, list down all those problems in your organization that have been occurring for more than 5 years now, manifesting itself in some form or the other, in spite of a series of efforts year on year to arrest it. I have noticed that after some time, there is an innate acceptance in the organization that this problem is like the seasonal flu, it will keep coming again and again, we can’t do much other than taking precautions and facing it’s aftermath. In corporate, such perennial problems start off a mill of finger pointing rituals targeting other functions, individuals, company policy, customers, and even competition.

A comprehensive 5 Why Analysis should identify the systemic root cause of any problem. Some problems don’t need deep analysis at system level. Depending on the severity and occurrence of a problem, it should be possible to prioritize energies in identification of System level root causes wherever required.

3L 5Why analysis, represents 3 Level 5 Why analysis performed around the same symptom.

The 3 levels of the 5 Why analysis implies, performing 3 different 5 why analysis on the same problem from 3 different perspectives –

- Specific to the problem

- Specific to the detection mechanism

- Specific to the systemic issue

Here’s is how I use this method with my client projects and for coaching teams during my engagements (and it’s a little different from what others do with 3L 5 Why):

- Level 1 – Specific to the problem – Perform 5 Why analysis for the issue on hand. It can be related to customers, regulators, safety, quality , productivity or any other significant failure. Usually this is done by the people closest to the processes in question, essentially the doers and immediate team leaders. The purpose of this level 1 5 why analysis is to identify the root cause for why the problem on hand occurred. For ex: Lets say, your regulator has fined you for non-conformance in a standard laid out by them. Here, our focus will be on : Why did we get fined now?

- Level 2- Specific to the detection mechanism – Ideally this level of analysis has to be done by managers. They have laid out processes, controls, checks and balances to ensure critical issues are identified before it goes outside the organization. So the focus of this level of 5 why root cause analysis will be to identify the root causes for why the detection system allowed defects to pass downstream. Hence addressing this area will strengthen the control and governance system. For ex: Why did the transactions escape the automated checks, human checkers, approvers, auditors, process owners, etc

- Level 3 – Specific to the systemic issue – The last and highest level aims to look for systemic deficiencies that lead to the problem. From my experience, this requires a very good understanding of the entire value chain. Actually it also requires a candid acceptance of flaws in the enterprise such as culture issues, process deficiencies, silos, resourcing gap, ineffective leadership, etc. Ideal for senior leaders to deep dive to identify system level root causes. From my experience, this is best done at periodic intervals by combining the study of several similar L1 and L2 failures. Most of them converge to a handful of common system level root causes. Unfortunately, the hard hitting reality is that these are conveniently ignored. For ex, in the case of compliance issue we touched earlier, an example of system level cause is, employees are held accountable for their mistakes and it directly impacts their growth and C&B; And so most of them wish to cover up anything that occured, even if it was inadvertent.

There are several practical strategies that need to be developed to improve the effectiveness of 3L 5 Why analysis depending on culture, know-how, sector, etc.

Another important missing link to 3L 5Why analysis is the data based validation. It is almost impossible to get to the root cause by merely brainstorming. An ideal approach would be to use a triangulation method.

#nilakantasrinivasan-j #canopus-business-management-group #B2B-client-centric-growth #3L-5Why-Analysis #5Why-Analysis

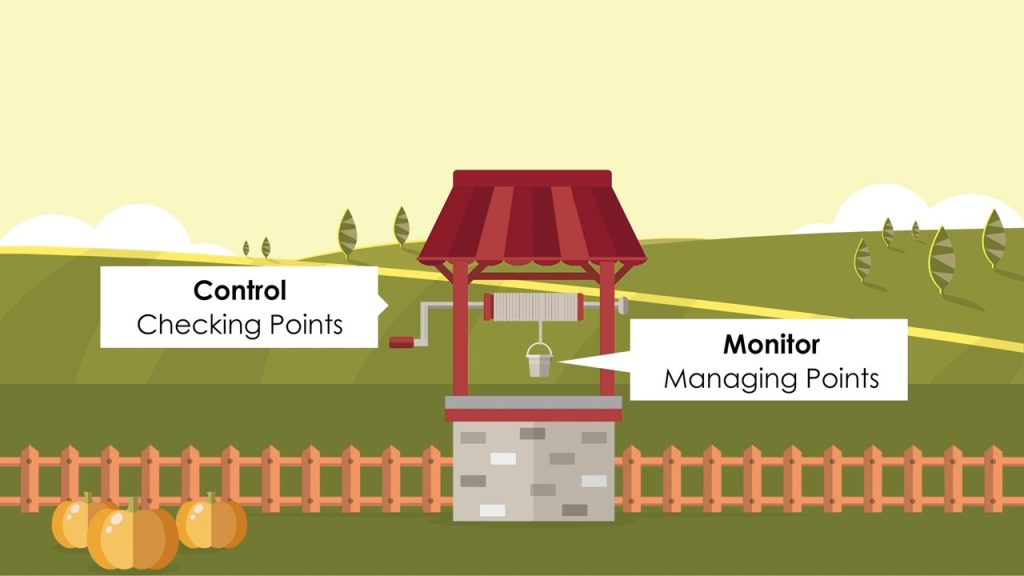

There is a good chance that you haven’t heard of these terms – Managing Points and Checking Points or MPCP.

Now, we will talk about what are ‘MPCP’ and why they are needed, with an example.

In order for you to fully relate to MPCP, you will need to have some background in Daily Work Management and Standard Work.

In an organization, there would be two kinds of activities or goals – Run the Organization (Daily Work Management) and Change the Organization (Transformation or Improvement). For example, if you wish to sustain existing revenue, you would want to maintain or upkeep many process parameters and initiatives through regular management, reviews, support existing products with improvements, provide enabling tools, resources, etc. These fall under Daily Work Management. And when you wish to shift gears and accelerate the business and grow 10x, then you will be looking for Transformation, ie., developing new products, adding new facilities, hiring more people, acquiring new technology, etc.

Managing Points and Checking Points (MPCP) are part of the Daily Work Management routine. They are a set of accountability and responsibility areas for a given role in the organization, aimed mainly at sustaining current level. This could include small improvements to fix issues, address day to day issues, monitor current state of process, ensure there is no deterioration of performance, etc. One of the biggest goals of DWM is to reduce the variability in the output or in other words bring in consistency in the system.

You may be confused about how MPCP is different from Annual Goals or KRAs? Remember that MPCP is for a role and Annual Goals and KRAs are for individuals. Thus it is very unlikely that MPCP would change year on year for role, of course unless the role scope has changed. They are also independent of title.

Now let’s understand Managing Points.

Managing Points are representative of accountability of any given role. For example, a CEO is accountable for business growth, employee engagement, compliance to law of the land, fair treatment to vendors, etc. So he/she has to oversee these aspects. He can’t tell the Board that my Sales Head had a bad year and so we didn’t meet the target. So Managing Points arise from the job description or role description. It also emanates from what the Board or his superiors want him/her to do. In case of any other employee in the organization, Managing Points (MP) are derived from 3 sources – Role description, Manager’s MP and Manager’s CP.

Now let’s move to Checking Points.

Checking Points are demonstrations of responsibility for any given role. These are metrics, tasks or activities that you will do to ensure your accountability is delivered. For example, a kindergarten teacher is accountable to ensure the kids are safe in the classroom. They don’t eat a crayon or anything like that. She will constantly check the classroom for littering, keep close watch on hyperactive kids, etc. So this becomes her responsibility. If I expand the definition of Checking Points (CP) a bit, then it covers input and process parameters, adherence to standard operating procedures (SOP), leading indicators of managing points so that necessary course correction can be done, etc.

A well designed MPCP system for any role should include 2 to 3 CPs for any MP and no more than 5-6 MPs for a role.

Let’s consider one more example of MPCP. Consider you are driving down to pick up your Chairman from the airport. He is visiting your country office for the first time after he took over and you don’t want to mess it up. It’s a 90 mile drive from your factory. You have a driver and a colleague with you. Your Managing Point will be to ensure you reach the airport on-time. Always remember Managing Points have to be measurable parameters. So what will be Checking Points (CP) for this Managing Point (MP)? The departure time from factory, route to be taken, when and where to stop over, average speed, who should be the driver, ensuring the car has all necessary travel documents, etc.,

Each one of the items mentioned here can become your Checking Point but usually the critical ones are prioritized. Some of them, you may choose to delegate to your secretary or empower the driver, in which case it may become their MP. But they are still your accountability.

Let’s say, the route you initially chose has congestion, you will ask the driver to take a different route and not stop-over to compensate for the time lost. Thus you have to measure or assess Checking Points (CP) more often than Managing Points (MPs) to get desired results.

I hope through this example, you were able to understand the importance and linkage between MP and CP.

In a large organization, MPCPs of various roles have to be interlinked. So MPCP plays the vital role of linking job responsibility, process standards and, link to manager or subordinate roles.

At Canopus, we have facilitated the development MPCP and some of most frequently asked questions from participants include:

- How is MPCP different from Annual Goal Sheets?

- How is MPCP different from Projects and Special Assignment?

- Will my MPCPs change every year?

- Can I assign MP or CP to my peers or other departments?

If you have similar questions, feel free to contact me and I’m happy to guide. You can also take self-paced online course Standard Work that will give you templates and many more examples.

#nilakantasrinivasan-j #canopus-business-management-group #B2B-client-centric-growth #MPCP

Arun was a Regional Head for Channel Expansion & Relationship for a white goods manufacturer. This year he received an award for outstanding performance for a record appointment of new channel partners (distributors and retailers) in a region that was considered as a weak territory for the company. The CEO said that this was a recognition of his problem solving skills.

It all started last year with the company setting an ambitious target to expand its network. In the first 2 quarters, there wasn’t much break through in the channel appointment. Management decided to move Arun from another region to drive this goal. Arun is known as a messiah in the company. Whether it is revenue, market share growth, network expansion, new product penetration, he is known for miraculous improvements. He could turn deserts into oases. His patrons say he’s very systematic and focused. While his critics claim he micromanages things. Nonetheless, as predicted, within the remaining 2 quarters of the FY, Arun swiftly throttled the appointment of dealers and distributors, thereby exceeding the original annual target set, which at the end of 2nd quarter looked un-accomplishable. Management’s aspiration was nothing more than achieving half the annual target set in the beginning of the year, with only 2 quarters in hand. So messiah proved his metal again!

What did Arun do differently?

- He put a progress tracker in place

- He broke the partner appointment process into various milestones

- He ensured there is a daily review of all district appointment managers against the milestones.

- In the reviews, he will dig deeper and deeper into cases where there was doubt of closure.

- He personally spoke to prospective distributors and even visited a few in person

- He increased the local media advertisements calling for partners to join.

Though all this might sound very intrusive, the fact is he got it done!

All is not rosy about Arun. There is one minor problem in our Messiah. Whenever he is done and moves to another role or area, all the old problems crop up again. Arun used to take pride in this, that once he leaves things fall flat. He was sure this is a way to let the management realize his value.

Was Arun really a good problem solver? Or is he a trouble-shooter?

| Trouble-shooter | Problem Solver |

|---|---|

| Always fixing the performance is his/her goal | Defines what is really the problem to be solved |

| Provides short term fixes | Identifies the root causes of the problem |

| Focuses on improvement in output | Validates system level root causes with facts or data |

| Doesn’t openly share insights & only emphasizes on prognosis | Shares his/her findings & insights with others |

| Works in silos & uses his charisma as a leverage | Engages the stakeholders on ground to provide eradicate the problem permanently |

| Usually gives quick fixes as such solutions give results faster | Puts permanent solutions that are sustainable |

| Cadence is limited to his tenure | Create cadence to sustain the improved state beyond him |

| Keeps his team in suspense, fear & pressure | Makes it a Team Oriented Problem Solving (TOPS) approach |

I will allow you to decide where Arun fits better.

After all, he never examined why this territory had low network penetration? What is the perception of existing and prospective channel partners about the brand? Are existing channel partners profitable and satisfied? Is channel partner attrition a problem? What is it that the competitors are doing differently than us? What is the deficiency of channel management team in this region?

At best, he is a good mercenary.

More importantly, not everyone who gets things done are problem solvers. Simply put, true Problem Solvers leave everything a little better for others than they found it!

#nilakantasrinivasan-j #canopus-business-management-group #B2B-client-centric-growth #Problem-solver

Is there a difference between Six Sigma and Lean Six Sigma?

Lean and Six Sigma are close cousins in the process improvement world and they have lot of commonalities. Now we will talk about the difference between Six Sigma and Lean Six Sigma.

Six Sigma uses a data centric analytical approach to problem solving and process improvements. That means, there would be time and effort in data collection and analysis. While this sounds very logical to any problem solving approach, there can be practical challenges.

For example, some times we may need data and analysis to be even prove the obvious. That is lame.

On the other hand, Lean Six Sigma brings in some of the principles of Lean. Lean is largely a pragmatic and prescriptive approach. Which implies that we will look at data and practically validate that problem and move on to prescriptive solutions.

Thus combining Lean with Six Sigma, helps in reducing the time and effort needed to analyze or improve a situation. Lean will bring in a set of solutions that are tried and tested for a situation. For example, if you have high inventory, that Lean would suggest you to implement Kanban.

Lean is appealing because most often it simplifies the situation and that may not be always true with Six Sigma. However the flip side to Lean is that if the system have been improved several times and reached a certain level of performance and consistency, Lean can bring out any further improvement unless we approach the problem with Six Sigma lens, using extensive data collection and analysis.

Looking at the body of knowledge of Six Sigma and Lean Six Sigma, you will find that Lean Six Sigma courses following tools:

- Cost of Poor Quality

- Lean Principles

- Definition, Origin, Principles & Goals of Lean

- Value, Value Stream, Concept of Muda(Waste) & Categories of Waste

- 7 Types of Wastes, How to Identify them, & Waste Identification Template

- Value Stream Mapping (VSM), Symbols, Benefits & Procedure

- Push System, Pull System, Single Piece Flow, 5S, Kaizen, SMED, Poka-Yoke

- Types of Poka-Yoke – Shut Down, Prevention, Warning, Instructions

- Heijunka & Visual Control

#nilakantasrinivasan-j #canopus-business-management-group #B2B-client-centric-growth #Lean-six-sigma #six-sigma-green-belt-certification #six-sigma-black-belt-certification

Is Lean Six Sigma still relevant?

In the age of AI and ML, where everything is getting automated, why would any one need an approach will can improve the process. Yes, mostly processes are set to become automated and that means they are already optimized. Will there at all be a need or scope to improve them any further?

Lets now look at how digital transformation is going and its adoption across sectors:

- Internal acceptance and adoption is slow for digital transformation technologies and expected ROI remains an aspiration

- People have come to realize that Digital Transformation is a journey and not a ‘fix it and forget it’ model.

- Digital Transformation is a continuum of iterative improvements leading to big transformation and so even when it is digital change, they have to move step by step

- People are not going to go away and hence success of such transformation will reside largely on how people behavior change is addressed and technology change will take care of itself

- Every employee will have to have a keen eye for improvement and find ways to transform the business.

- The only differentiation between competition and you, is how you will react to a situation, because your competition would have the same technology advantage as you. That means, change is constant and your employees have to look for newer ways of doing things and technology is just an enabler

Lean Six Sigma is a way to challenge status quo, a way to solving problems and make improvements.

With AI and ML, neither will the need to challenge status quo or solve a problem or make improvements go away. In fact they will become even more challenging. That would mean, the need for Lean Six Sigma tools and techniques will be all the more important.

No Digital transformation commences without a good As-is analysis. The tools and techniques used for performing this are tools used in Lean and Six Sigma. Similarly, identifying how much improvement can be brought about requires going to the root of the problem. Technology solutions that are superficial will only add to the complexity and not simplify the business.

Thus even skills needed for Digital Transformation are part of Lean Six Sigma body of knowledge.

To be very specific, Lean Six Sigma Certifications will definitely be an added advantage in days to come which are dominated by AI, ML and Digital transformation.

Python for Lean Six Sigma Professionals

We have launched a new online course for Six Sigma Experts like you : Python for Six Sigma Professionals.

Course Information

Estimated Time: 300 Minutes | 30 Lectures | Price : $59.99

Use Coupon code: PLSS19#

To Get this Course for $19.9 Now

(Valid till 12 Jul 2019)

Why you should consider this PYTHON course?- You are already exposed to Lean Six Sigma Data Analysis & Discovery using other tool such as Minitab, Excel, JMP or SPSS

- There is no need to emphasize the importance of Data Science in today’s Job Market

- You have an added advantage because of prior Six Sigma Data Analysis proficiency

- But Python is the most popular and trending tool for Data Science now

- In current scenario, if you are not able use Python to do Data Analysis, it’s obvious what you are missing!

- Learn Lean Six Sigma Data Analysis in Python

- Step by Step Procedure for all Six Sigma Analysis is covered

- No Programming Experience Needed. Course will even help you do Python installation

- Six Sigma Tools Covered using Python

- Data Manipulation in Python

- Descriptive Statistics

- Histogram, Distribution Curve, Confidence levels

- Boxplot

- Stem & Leaf Plot

- Scatter Plot

- Heat Map

- Pearson’s Correlation

- Multiple Linear Regression

- ANOVA

- T-tests – 1t, 2t and Paired t

- Proportions Test – 1P, 2P

- Chi-square Test

- SPC (Control Charts – mR, XbarR, XbarS, NP, P, C, U charts)

- Python Packages

- Numpy

- Pandas

- Matplotlib

- Seaborn

- Statsmodels

- Scipy

- PySPC

- Stemgraphic

- One Full Fledged Lean Six Sigma Case Study with Solutions (in Python Scripts)

- Download all Python Source Files for all the analysis

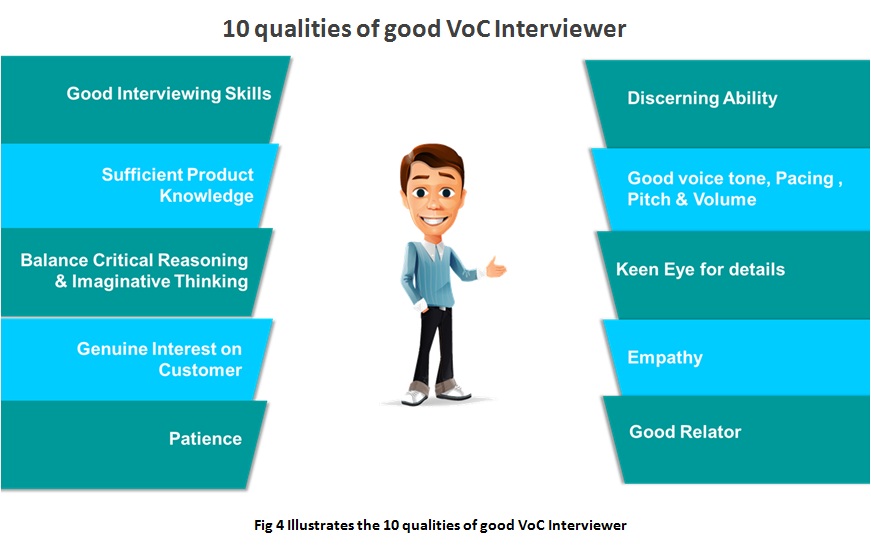

10 Qualities of Voice of Customer (VOC) Interviewers

Voice of Customer Interviews are very critical because it is not easy to get quality time from customer to share their views. When such an opportunity culminates, the VOC interviewer has to be effective enough to make the best out of it. Here are 10 qualities that are critical for any VOC interviewers:

Good interviewing skills: This is a critical skill in both in-depth VoC interviews and focus group moderating. VoC interviewers need to listen without judging, asking clear questions, probe, capture non-verbal clues, etc. Listening skills cannot be underestimated because if interviewer doesn’t actively listen to customers, he/she won’t be able to probe on the second, third and fourth levels. Listening skills and remembering their responses builds rapport and encourages the customer to offer more detailed input because they know the interviewer is listening.

Discerning ability: Very good VoC interviewers in an urban set-up may miserably fail in rural environment because; interviews with rural customers have to be in the form of general conversation. The interviewer needs to know when to ask specific questions and put an end to general discussion.

Sufficient product knowledge: Product knowledge of interviewer or moderator is non-negotiable. Without understanding the range of products – current and past and its corresponding competitor products a VoC interviewer will be a lame duck in front of customer.

Good voice tone, pacing, pitch and volume: This is often overlooked but it’s a key reason that differentiates the good VoC interviewers & moderators from the bad ones. Those who read directly from their guide and sound robotic, which discourages the customers, while, on the other hand, those who are overly lively and upbeat also turn off customers to silence. Somewhere in the middle might be the best bet.

Balance critical reasoning & imaginative thinking: Interviewers & moderators need to know the objectives of their VoC research beforehand. In case the participants are not giving them the in-depth information to address those objectives, they often have to think on their feet and get creative to get better responses. Thus VoC interviewers need to possess appropriate combination of critical reasoning skills and imaginative thinking skills.

Keen eye for detail: During interviews, several rapid, loosely related or unsolicited responses may originate from the customers. In fact, some of them may be non-verbal in nature. While such valuable information may go un-noticed, a good VoC interviewer will leverage his/her ability to observe with a keen eye for detail to unearth unarticulated needs of customers.

Genuine Interest on Customer: Ability to stay genuinely interested, as a person, and completely detached, as an interviewer is very important. There is a very delicate balance and a key success factor for any VoC researcher. One has to be genuinely interested in the discussion and actively listen to ensure that the customer feels comfortable and grows trust that they can be forthright in their opinion. Yet, one cannot bias the research through one’s demeanour. Thus one may build a great rapport with a participant right off the bat, but you need to stick to objectivity.

Empathy: While a VoC interviewer or moderator has well defined objective for each interview, customers may come from a different frame of mind, culture, upbringing and generation. In fact they may be grappling with problems which are far more important than the ‘position of gear handle’ or a need for a ‘water bottle holder’. A good interviewer should first empathize with the customer, even if it means putting aside his/her viewpoint, and try to see things from customer’s point of view. Again, customer may be illiterate, economically not well placed, etc., but respect him and his views.

Patience: The VoC interviewer needs to have a lot of patience to get specific responses from rural customers, as they may get involved in their rhetoric and repeat things. The VoC interviewer has to tactfully bring them back on track.

Good Relator: As a good relator, VoC interviewer or moderator will focus on building relationships with customers that go beyond short term transactions such as VoC Interviews for an hour. He/she will need to understand customer’s feelings, their goals, their fears, and their dreams. A good relator will not shy away from meeting new people, every day and will derive a great deal of pleasure and strength from being around their customers.

Measure Phase of Lean Six Sigma Project is the second phase. Following are the deliverable of this phase:

- Identify all possible causes (Cause & Effect Diagram)

- Validate Measurement System, Data Collection & Sampling

- Establish Process Capability

Identify all possible Causes (Cause & Effect)

In the measure phase of a Lean Six Sigma Project, the team brainstorms to identify all possible causes or reasons for the occurrence of the problem. Thus, there is a direct linkage between a project charter and this deliverable. Fish-bone diagram is a structured brainstorming method used to carry out this activity. Fish-bone diagram is also called as Ishikawa or Cause & Effect diagram. After completing this brainstorming, the team applies the 5-why technique to further explore the underlying causes for all the reasons identified in the fish-bone diagram. At the end of these two activities, the team has an exhaustive list of possible causes for the problem. Usually there are around 50~100 possible causes for the problem. It is the responsibility of Six Sigma Green Belt to facilitate these activities. As a next step, using their process knowledge and experience, the team has to agree on few causes; which potentially cause the problem. There are several methods to do this, but the most popular method is the use of Cause & Effect Matrix (C-E Matrix). Potential Causes are suspects that are causing the problem. However, before acting on them, the team needs to gather data or facts to validate them.

Validate Measurement System, Data Collection & Sampling

Data Collection plays a very important role in all Six Sigma projects. But before collecting data, the team has to assess if the measurement system (measuring instrument, appraiser & environment in which measurement happens) is accurate and precise. Hence the team has to perform Measurement System Analysis (MSA) – aka Gage R&R. Once the team ascertains that the measurement is good, then a data collection plan is prepared. Data Collection Plan (DCP) includes the measures whose data needs to be collected, how much data to collect, data source, and who will collect the data, etc. While the entire team can participate in this activity, Six Sigma Green Belt has to take a lead role, as this will involve technical concepts of Gage R&R covered in the training program. Unlike conventional data collection; in Lean Six Sigma projects, data is collected on both the CTQ and the potential causes identified in a Cause & Effect Matrix. Due to the quantum of data involved in most businesses, it isn’t practically viable to collect data of the entire population. Hence the team has to resort to statistical sampling methods. As a next step, data collection is executed. From time-to-time a Six Sigma project team needs to validate the data collected. Sometimes, the data collectors need to be trained and retrained. Once the data collection is complete, it is ready for a process capability assessment. Usually many projects get delayed because of poor data quality or delay in collecting sufficient data. When a Six Sigma Green Belt takes special care, this activity can get completed on time.

Establish Process Capability

Process Capability is the ability of the process to deliver as per customer requirement. There are various process capability indices, but in Lean Six Sigma projects, sigma capability is the most popular measure. This exercise gives an accurate report on the current process performance. As these indices are covered in the training program, Six Sigma Green Belt has to take a lead role in conducting this study. The output of Process Capability study can be used to validate the process objectives and anticipated benefits in the charter. If needed, the Lean Six Sigma project charter can be revisited. On completion of the above deliverable, and a formal Measure Phase tollgate review, the team is ready to move into Analyze phase.

If you are new to Lean Six Sigma then Y=f(X) is one amongst many jargons that you will have to familiarize yourself.

The objective of Lean Six Sigma philosophy and DMAIC improvement methodology is to identify the root causes to any problem and control/manage them so that the problem can be alleviated. Six Sigma is process oriented approach which considers every task as a process. Even the simplest of the tasks, such as performing your morning workout or getting ready to office is considered as a process. The implication of such a view point is to identify what is the output of that process, its desired level of performance and what inputs are needed to produce the desired results. Y is usually used to denote the Output and X for the inputs. Y is also known as dependent variable as it is dependent on the Xs. Usually Y represents the symptoms or the effect of any problem. On the other hand, X is known as independent variable as it is not dependent on Y or any other X. Usually Xs represents the problem itself or the cause. As you will agree that any process will have at least one output but most likely to have several inputs. As managers, we all are expected to deliver results and achieve a new level of performance of the process such as Service Levels, Production Levels, Quality Levels, etc., or sustain the current level of performance. In order to achieve this objective, we focus our efforts on the output performance measure. However a smart process manager will focus on identifying Xs that impact the output performance measure in order to achieve the desired level of performance.How does one identify the input performance measures or Xs? Six Sigma DMAIC methodology aims to identify the inputs(Xs) that have significant impact on output (Y). After that the strength and nature of the relationship between Y and Xs are also established. Six Sigma uses a variety of qualitative and quantitative tools & techniques listed below to identify the statistical validation of the inputs (or root causes), their strength and nature of relationship with Y:

- Cause and Effect Diagram/Fish Bone diagram

- 5 Why Analysis

- Process Maps

- Histogram

- Descriptive Statistics

- Run Charts

- Normal Distribution Plots

- Box plots

- Stem and Leaf Plots

- Hypothesis Testing

- ANOVA (Analysis of Variance)

- Chi-Square Test

- 1-t Test

- 2-t Test

- Paired t Test

- Correlation

- Regression

- Scatter Plots

- Statistical Process Control (SPC)/Control Charts

What does f in Y= f(X) mean? ‘f’ represents the nature and strength of the relationship that exists between Y and X. On one hand, this equation can be used for a generic interpretation that symbolizes the fact that Y is impacted by X and nature of relationship can be quantified. On the other hand, such a mathematical expression can be created provided we have sufficient data using the above mentioned analytical tools such as regression and other hypothesis tests. The mathematical expression that we obtain is nothing but an equation such as: TAT = 13.3 – 7.4*Waiting Time + 1.8*No. of Counters – 24*Time to Approve Once such an equation is established, it can be easily used to proactively identify the Y for various values of X. Thus Y= f(X) is the basis for predictive modeling. All the newer analytical concepts such as Big Data, etc are based on this foundation principles.

Whatever is the nature of your business, innovation is critical today. In order to survive competition and be the customers’ choice, you need to come up with really new products and services. All it means is that your ability to manage the change is a direct measure of your success. In other words, timely launch of new products/services in desired quality and price are going to determine your success, apart from cultural change aspect. So whether you want it or not, good project management skills are essential in today’s business to survive and win. Without digressing on other pre-requisites of good project management, let’s focus on one of most important but rarely focused area.

There are several project management techniques and tools available such CPM, PERT and Critical Chain. Immaterial of the base on which these models are structured, out of my experience, everything finally boils to predicting time duration for a task and the delivering as predicted. In small organizations(less than 10 employees), it is more of coordination, multi-tasking and communication that will determine if a task can be completed as predicted. But with organizations involving a few tens of employees, it is all about how resources and efforts are synchronized. There may be lack of knowledge of what is to be done next, on who owns which piece, how & when to escalate lack of clarity on authority and decision making. Additionally unlike bigger organizations, smaller companies will have to manage with inexperienced and understaffed scenarios. So to make life easy for everyone, if processes associated with project management such as supply chain management processes, finance processes, clearly defined inter-department service levels and authorities, etc., are established well, that will help the organization deliver projects in time. Isn’t this what ‘Process Management’ is all about! Mathematically also it makes sense to focus on process management. For instance, consider the PERT model in which the PERT Time (Task duration) is a function of Optimistic Time (OT), Most Likely Time (MLT) and Pessimistic Time (PT). When OT and PT are wide apart, it means that it is not possible to predict the task duration accurately. In other words, the process on which the task is dependent has high variation. Such a process leads to higher PERT Time. When all the tasks of the project have widely spread OTs and PTs, the overall project duration itself will be high and unpredictable. In order to have closely defined OTs and PTs, we should have confidence that our processes will consistently deliver on-time. In other words, our process should be statistically under control and stable. Again, it’s Process Management!

Six Sigma is a combination of the best elements of various quality improvement methodologies and a rigorous statistic-driven approach to performance improvement. The term “Six Sigma” was coined by Bill Smith, an engineer at Motorola. Six Sigma, in the present form, originated in the early 1980s at Motorola as a tool for reducing product-failure levels by 10 times in five years. General Electric (GE) implemented Six Sigma in 1995 after Motorola, and Allied Signal followed the Six Sigma trail after GE.

Six Sigma methodology evolved by combining the best elements of earlier quality improvement innovations.

| Innovation | Description |

| Uniformity system |

|

| Moving assembly line |

|

| Control charts |

|

| Quality movement |

|

| Customer Centric Products |

|

| .Zero defects |

|

| Quality standards |

|

| Six Sigma |

|

Sign-up for collaborat newsletter